General speaking ,an appearance prototype requests surface effect close to real product so the designer can test appearance effect.Common appearance treatments are Sanding ,base grey spraying,polishing,painting,silk-screen printing,electroplating,etc.

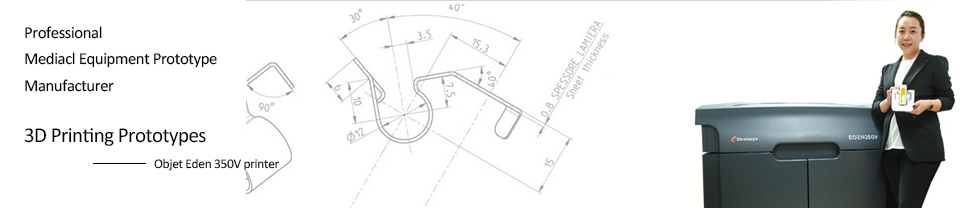

There can be 3 different kinds of sanding methods of prototype:dry Sanding,wet Sanding and machine Sanding.Today Shenzhen Ebyton Technology Co.,Ltd will share some points about wet sanding of prototype here for you.

Wet sanding it to dip the abrasive paper in water or soapy water,then grind the prototype with it.Wet Sanding can relatively reduce the sanding marks and bring more smooth surface to the part by spending less abrasive papers and efforts.

However, it should be noted that the part cannot be painted until the part’s completely dry after wet sanding, otherwise the paint is easily blushing.

And also note that, materials which is highly water absorbent should not be wet sanded,like PA(Nylon).Because they will expand when touching water,thus will affect the prototype precision.

If you are interested in EbyTon,or any assistance needed,contact us or just call us at +86 755 28102539.EbyTon --Shenzhen Top supplier of prototypes manufacturing & sheet metal parts fabrication! |