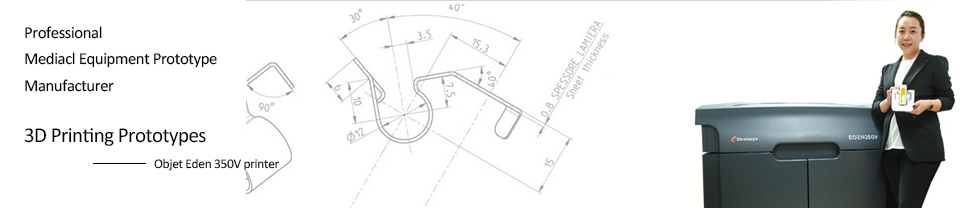

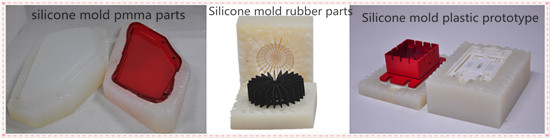

Shenzhen EbyTon Technology Co.,Ltd is engaged in prototype making for more than 9years by 2014,and focus on cnc machining,sla,sls,3d printing and silicone mold for small produxtion.While on silicone mold vacuum casting process,we often meet some problems.Next let’s see what are they as follows:

1.Sticky mold .

EbyTon specialists assume that there are two reasons for this problem,

Reason one: Because at earlier stage,the original prototype was not handled well before mold building.So EbyTon specialists suggest that before building the silicone mold ,we must handle with the prototypes carefully,especially for those with rough surface or with relatively complex structures,must carefully sanding to smooth and clean them up. Then evenly paint release agent on the faces. Commonly used mold release agents are: Vaseline, detergent, liquid paraffin. In practice can be painted different kinds of release agent as different materials.

Reason two:Curing agent is poured into the mold without stirring on balance first,leading to a dry piece and a not dry one when the prototype is get out of the silicon mold.

2.Uneven curing happens after silicon mold is solidified.

Similarly ,EbyTon’s specialists summerized two main reasons for it as below,

First .The ratio of silicone and curing agent is not accurate and not weighted as required

Second.Operators didnt stir even the silicone with the curing agent when mixxing them together.This will lead to the mold scrapped, so we should try to avoid this mistake during silicone mold prototype making.

If you are interested in EbyTon,or any assistance needed,contact us or just call us at +86 755 28102539.EbyTon --Shenzhen Top supplier of prototypes manufacturing & sheet metal parts fabrication! |